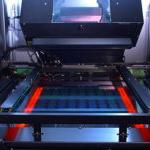

兰开斯特金属科学提供传统的离散金属板蚀刻和, since 1989, continuous reel-to-reel processing. In application, 连续制造与板材制造相同,除了所有的加工步骤-从清洁金属到应用光刻胶到紫外线成像,最终到蚀刻金属和剥离光刻胶-都是在线圈上进行的,而不是在金属板上进行的. The final product, then, 提供给客户的不是单独的零件或一个零件面板,而是一个连续的线圈.

Our Advantage

兰开斯特金属公司的卷轴对卷轴蚀刻的核心是能够对连续的条带进行成像,并在顺序曝光和成像的面板之间保持精确的配准和对齐. As digital imaging technology evolved, 在制造业中得到改进和推广, 它在光化学蚀刻产品的卷对卷印刷中找到了出路. 2007年,兰开斯特金属公司升级了其卷筒到卷筒印刷,采用了第一台采用数字成像和光学瞄准的机器,以实现精确的面板到面板的配准和对准. 2018年,兰开斯特金属公司基于同样的技术增加了第二条打印线,并结合了前十年的所有进步,包括使用LED作为光源. 两条线都采用多个CCD相机来定位许多预定义的目标,以实现最佳的面板到面板对齐.

制造的零件要经过完整的首件检查,以确保满足所有打印尺寸.

Using multiple 2D optical micrometers, 兰开斯特金属还提供在线检查蚀刻带在发展结束, etch and strip line. In real time, critical dimensions are monitored, 记录并及时反馈整个蚀刻作业的效果.

作为最后的离线检查,所有蚀刻带材都通过高速机器视觉系统运行. 兰开斯特金属公司的视觉系统能够同时检测金属表面和蚀刻零件的几何形状.

兰开斯特金属公司在传统面板上蚀刻的任何金属,包括铜, 铝和不锈钢可以在这种卷到卷的格式进行加工. All the advantages normally associated with metal etching including the production of burr-free parts; the ability to produce fine, intricate geometries; dimensional repeatability; the ability to etch surface features such as grooves or channels and the cutting of metal without disturbing the intrinsic characteristics of the base metal are also present in continuous processing. In addition, 卷轴对卷轴蚀刻的工具要求与与离散板蚀刻相关的低成本工具相当. During imaging, 模具的持续尺寸精度由卷筒到卷筒印刷线本身的环境控制来保证,并由系统测量和监控模具尺寸的能力来验证.

Additional Benefits

虽然在这种连续的格式中,金属蚀刻零件的高产量可能会产生某些经济效益, 客户还可以获得额外的好处. 连续带材的零件允许任何后续的制造步骤-电镀, forming, die-cutting, insert molding or assembly, 例如,在连续的卷轴到卷轴的基础上进行.

For metals less than 75 microns in thickness, whether because of the thickness, temper or the complexity of part design, 卷对卷蚀刻为大批量生产提供了解决方案. 或用于最终通过级进模进行高冲程冲压的零件, 考虑卷轴对卷轴蚀刻作为一种快速和廉价的方法来生产原型,甚至用于预生产运行. 允许卷轴对卷轴蚀刻是你的修剪模具,让所有后续的操作-成形, 电镀或过度成型-以高效率和成本效益的卷对卷方式完成.

在一个一切都变得越来越小的世界里, 更薄,更复杂,上市时间越来越短,定制而不是大规模生产正在成为规则, 卷对卷蚀刻为现代制造业提供了一些独特的解决方案.

Contact 我们的工程部可以评估您的具体要求.

连续卷对卷金属蚀刻服务

Specifications

- Continuous Reel-to-Reel Metal Etching

- Single and Double Sided Exposure Capability

- Chemical Blanking

- Chemical Etching

- Chemical Milling

- Photo Etching

- Photo Milling

- Photochemical Etching

- Photochemical Milling

- Photochemical Machining

- Copper

- Beryllium Copper

- Phosphor Bronze

- Brass

- Mild Steel

- 300 and 400 Series Stainless Steel

- Precipitation Hardening Steel

- Aluminum

- Aluminum Alloys

- Nickel

- Monel®

- Inconel®

- Kovar®

- Molybdenum

- Carbon Steel

- Magnetic Alloys

- Spring Steel

- Alloy 42

- Invar®

- Low-Cost

- Fast Turnaround

- Design Flexibility

- Dimensional Repeatability

- 10%

- 显影,蚀刻,带线(铁和氯化铜)

- 2 Reel-to-Reel Print Lines

- Prototype

- Low Volume

- High Volume

- Blanket Orders

- Quoted on Job by Job Basis

Thickness

Length

Width

Additional Information

- Electronic Connectors

- Electromagnetic Interference (EMI) Shielding

- Radio Frequency Interference (RFI) Shielding

- Filtration

- Heat Exchangers

- Lancets

- Mesh & Sieving

- Perforated Metal Screens

- Circuits

- Mesh/Screen

- Aerospace

- Automation

- Automotive

- Biomedical

- Communications

- Computer and Electronics

- Dental

- Defense Industry

- Department of Energy (DOE)

- Department of Defense (DOD)

- Electrical

- Electronics

- Electromechanical Devices

- Material Handling & Processing

- Medical

- Medical Devices

- Military

- Oil, Gas, & Petroleum Exploration

- Oil, Gas, & Petroleum Extraction

- Optical

- Optics

- Research

- Robotics

- Specialty Machinery

- Surgical Devices

- Telecommunications

- Textile

- Tool & Die

- ISO 9001:2015 (国际标准化组织)

- RoHS(有害物质限制(合规))

- ITAR Registered

- AutoCAD (DWG, DWZ)

- DXF(绘图交换格式)

- JPG或JPEG(联合摄影专家组)

- PDF (Portable Document Format)

Electronic-demo-marketing@pppcr.net

买球平台

买球平台

海洋之神

2345网址导航

Hele-888-service@vvip168.net

金沙集团

jdb电子

大连中考网

365体育

Buying-platform-marketing@annapolishsathletics.com

东方LED网

潞安生活网

莱芜论坛

金联创—化工

搜房网南通租房网

郑州律师网

皇冠假日中国官方网站

南京第一夫人婚纱摄影馆

地宝网搜索

Electronic-demo-marketing@pppcr.net

买球平台

买球平台

海洋之神

2345网址导航

Hele-888-service@vvip168.net

金沙集团

jdb电子

大连中考网

365体育

Buying-platform-marketing@annapolishsathletics.com

东方LED网

潞安生活网

莱芜论坛

金联创—化工

搜房网南通租房网

郑州律师网

皇冠假日中国官方网站

南京第一夫人婚纱摄影馆

地宝网搜索